Revoria Press PC1120

The 6-color printer brings unparalleled expressive power to digital printing.

- Excellent productivity with high-speed printing of 120 pages per minute, even when printing in 6 colors.

- High resolution with a high output range at 2400 x 2400 dpi.

- High-performance print server that maximizes the productivity of the printing engine.

- Supports a wide range of materials: from 52 gsm lightweight paper to 400 gsm heavy paper, with a minimum size of 98 x 148 mm and a maximum size of 330 x 1200 mm.

- Various feeding and finishing options to optimize the workflow from printing to post-printing.

Main Features

Achieves both image quality and productivity at a high level.

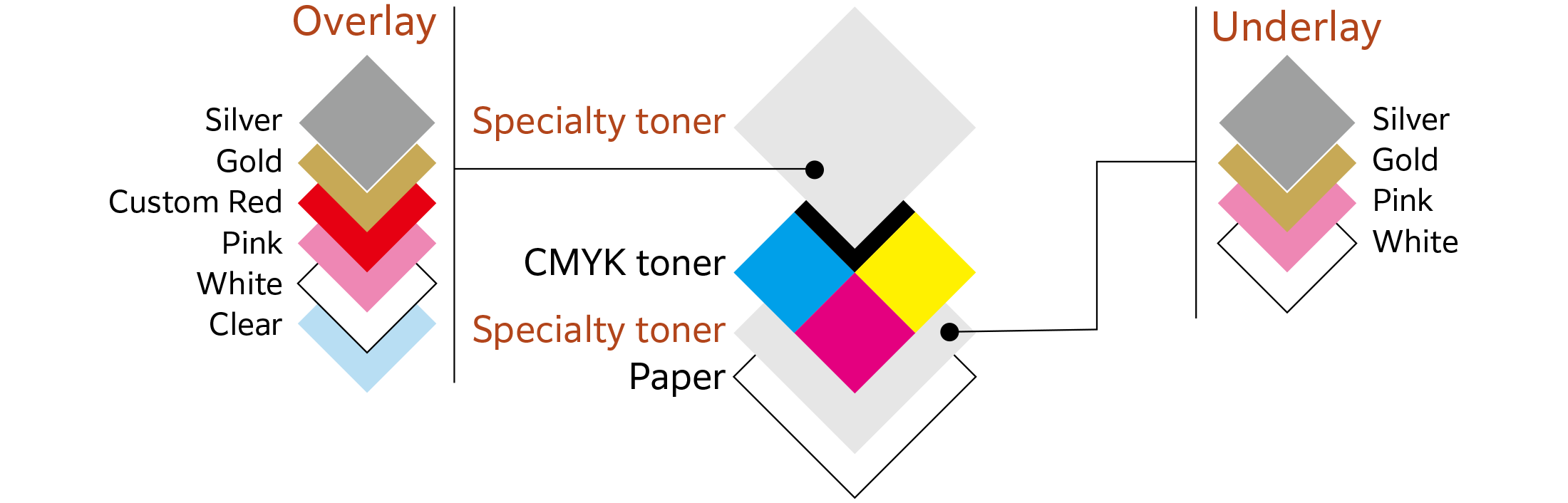

6-color printing in a single pass

In addition to CMYK toner, the printer can load up to two specialized toner stations. Options for specialized toner include clear*1, gold, silver, white, pink, and custom red*1 *2 toner. By combining CMYK with silver or gold toner, you can print various glossy metallic colors. Rich color expressions created by the 6-color printing engine can expand your business.

*1: Clear and custom red toner can only be used for overprinting.

*2: Custom red toner is available in limited countries.

Note: Users can replace specialty toner colors faster and easier than in offset printing.

|

With gold and silver colors, you can create various metallic effects. |

|

Pink toner can create attractive designs with fluorescent pink color. Note: Pink toner can be used to reproduce vivid red, orange, and purple colors in RGB. |

|

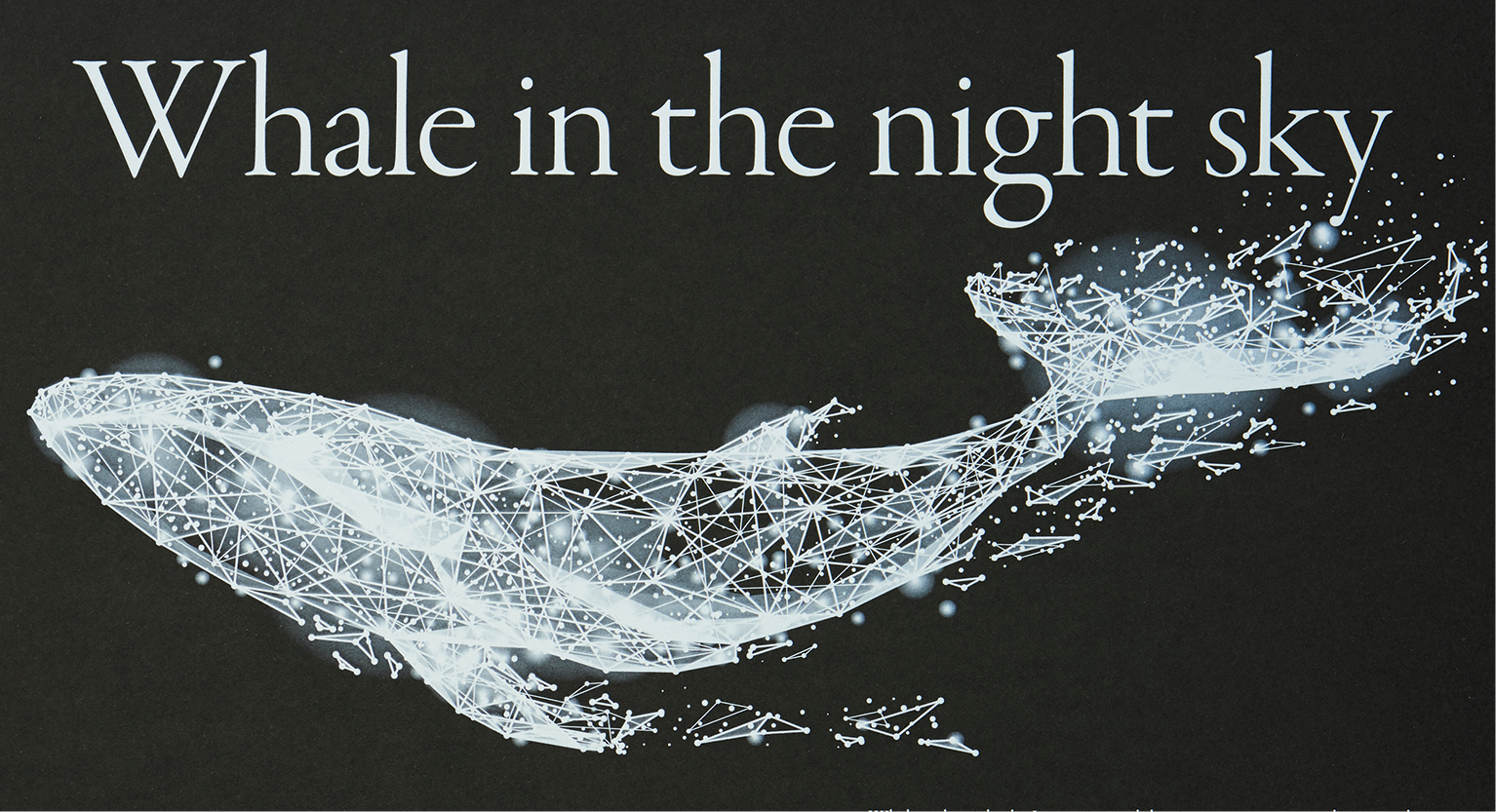

You can print on colored media with high opacity of white. |

|

White "underlay" printing can be used as a base for colored paper and transparent films. |

|

Clear and metallic colors are less prone to duplication and are effective on tickets, etc. |

High-resolution printing at 2400 x 2400 dpi

The heart of the printer, ROS*1, uses VCSEL*2 as a light source. It allows printing at high resolution of 2400 x 2400 dpi by drawing images simultaneously with multiple laser beams.

*1: Raster Output Scanner

*2: Vertical Cavity Surface Emitting Laser

Super EA* - Eco toner for high-quality images

Super EA-Eco toner with extremely small particles enables smooth reproduction of transitions in photos, uniform density, and sharper fine lines and text. It also creates more readable printed text with less glare.

*EA: Emulsion Aggregation

Easy and fast adjustments

The built-in sensor in the printer allows for easy and quick calibration. It also features an auto adjustment function that lets you adjust* multiple settings at once. This reduces the effort required for maintenance and downtime.

* Simultaneous adjustment of the following settings: auto alignment, correction of the second transfer roller, auto tone correction, density uniformity correction.

High-resolution print server with fast processing.

Image data processing to maximize printing mechanism performance

High-quality image data can be produced with RIP processing at 1200 x 1200 dpi and 10 bits (1024 levels of gradation) on the print server. Additionally, high-resolution and smooth images at 2400 x 2400 dpi can be created on the device using our unique HQ digital screen technology (MACS*). These data processing technologies can create high image quality derived from maximizing the performance of the printing mechanism.

* Micro Accurate Control Screen

Professional color management system

Supports various CMYK color standards such as Fogra, SWOP, and GRACoL.

Enhancing images in a better way

Higher image quality has been achieved with "Edge Enhancement", which corrects jagged edges of thin lines and text outlines, and "Adjust Invert Text / Line Weight", which corrects thickened/blurry text.

Note: Default setting: OFF

Selecting different screens for individual objects for optimal image quality

You can choose the appropriate screen for each object, such as text and photos. FM screen is effective against moiré patterns. The grainy coarseness that typically occurs with FM screens is suppressed by the dot arrangement suitable for the electrophotographic profile, enabling smooth image quality.

|

Making skin texture more beautiful Equipped with an image lighting function using fluorescent pink toner. By separating into CMYK + pink, skin tone can become brighter, and skin texture is reproduced smoothly and beautifully. Note: You can choose from three levels of effect. Since the pink layer is generated from magenta, it affects images that contain magenta. |

|

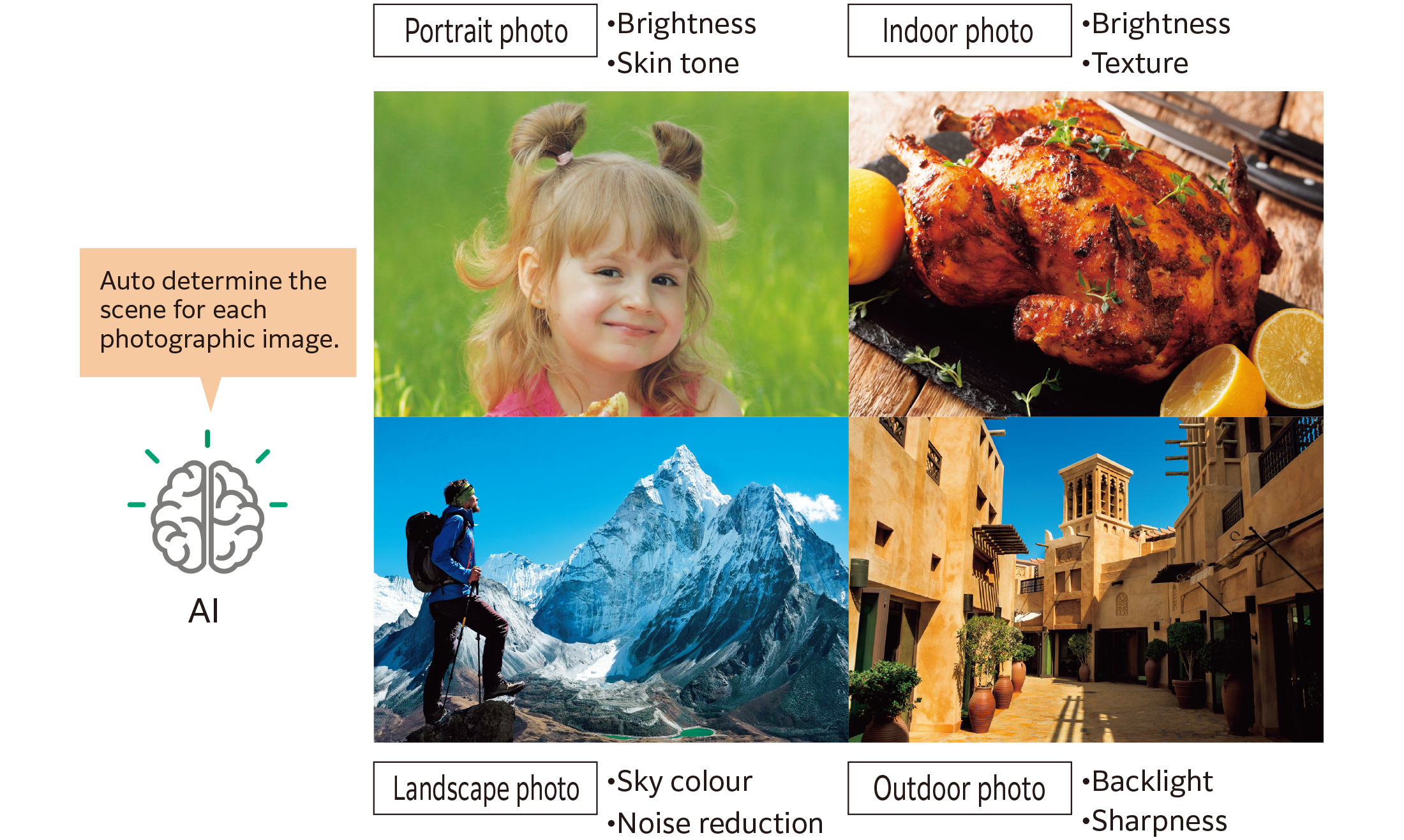

Photo quality optimization based on artificial intelligence*

Artificial intelligence (AI) automatically determines the scene for each photographic image on the page and appropriately corrects the image for each one individually. Low-quality images, such as those with poor contrast and brightness, can be automatically corrected.

* Applies to RGB type images.

A wide selection of media and output processing methods.

Support for a wide range of paper weights from lightweight paper of 52 gsm to heavy paper of 400 gsm.

Paper sizes range from A6 to 330 x 488 mm. Borderless printing is also possible in SRA3 format (320 x 450 mm), which is useful for creating brochures or flyers that require borderless printing.

Support for banner sheets up to 1200 mm long.

For single-sided printing*, you can print banner sheets sized up to 330 x 1200 mm. Expand the range of new printing applications, such as powerful panoramic posters.

Note: For printing banner sheets, contact our sales representative regarding the paper feeder or output module.

* Up to 330 x 729 mm for automatic double-sided printing.

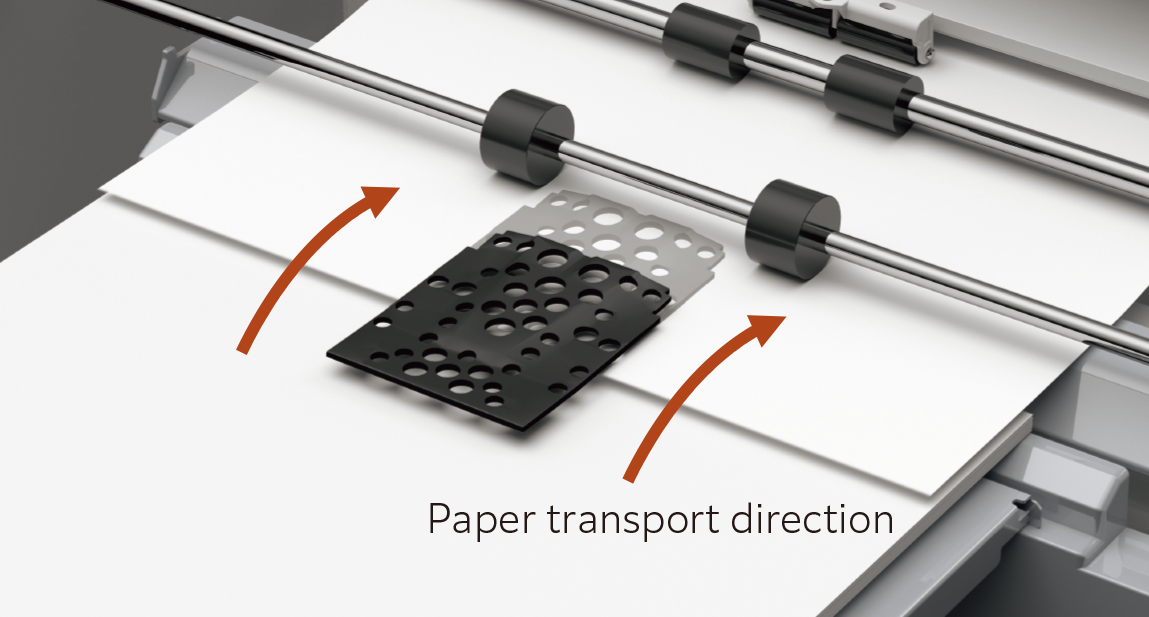

Static electricity elimination on film and metallic media.

Film and metallic media can easily become charged with static electricity during printing, causing printed media to stick together. However, the static elimination module* allows for easy stacking and alignment of these media.

* Optional: "Static Eliminator D1".

Various output finishing options*

With various trimming, folding, and creasing options, you can create different finished products.

* Optional

Connection of output units from other manufacturers*

Output units from other manufacturers can be connected in an "inline" line.

* Optional: "High Capacity Stacker A1 with transport module".

For more information about output units from other manufacturers, please contact us.

"Air suction feeder" or high-performance vacuum feeder for media handling

Each sheet is securely picked up and delivered by a head using air suction, which improves the paper feeding performance for low-quality, textured, and coated media.

Note: Optional configuration.

|

Automatic error checking Automatically checks for printing errors. The sheet can reject an error and automatically reprint it. This saves a lot of time and effort. Image review: Detects printing errors such as dots, stains, holes, lines, ears by comparing scanned images with RIP images in real time. Barcode/OCR review: Checks if printed barcodes or OCR fonts are readable, if the numbers are sequential, or if the numbers on page 1 and page 2 match. Stability: Print quality can be monitored by notifying changes in density or inconsistencies during printing.

Note: Additional options are required. For details, please contact our sales representative. |

Example of barcode printing |

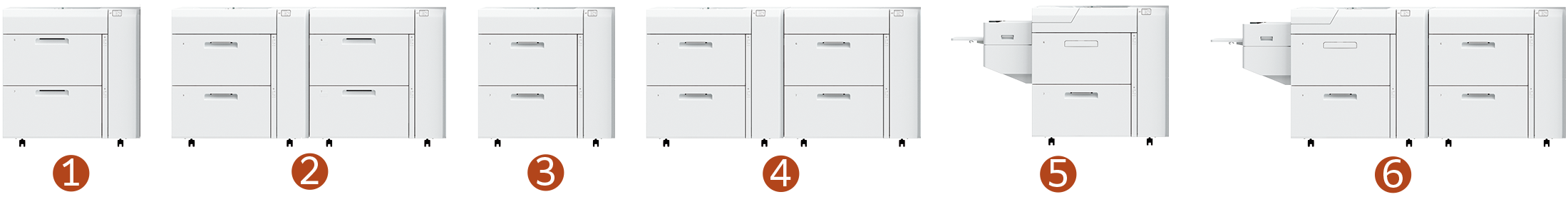

Input units:

1. High-performance feeder C3-DS + multi-sheet inserter*1

- Air assistance

- Multiple sheet feeding detection

- 2,000 sheets x 2 trays + 250 sheets

- Maximum size SRA3, 330 x 488 mm

2. High-performance feeder C1-DS + high-performance feeder C3-DS + multi-sheet inserter*1

- Air assistance

- Multiple sheet feeding detection

- 2,000 sheets x 4 trays + 250 sheets

- Maximum size SRA3, 330 x 488 mm

3. Vacuum feeder C1-DS*2

- Vacuum suction

- Multiple sheet feeding detection

- 2,100 sheets x 2 trays + 250 sheets

- Maximum size SRA3, 330 x 488 mm

4. Chain vacuum feeder C1-DS-L*2 + chain vacuum feeder C1-DS-R

- Vacuum suction

- Multiple sheet feeding detection

- 2,100 sheets x 4 trays + 250 sheets

- Maximum size SRA3, 330 x 488 mm

5. Vacuum feeder C1-DSXL*2 + banner unit for vacuum feeder C1-DSXL

- Vacuum suction

- Multiple sheet feeding detection

- Long paper feeding

- 800 sheets + 2,100 sheets + 250 sheets

- Maximum size 330 x 1,200 mm (top tray)

6. Chain vacuum feeder C1-DSXL-L*2 + chain vacuum feeder C1-DS-R + banner unit for vacuum feeder C1-DSXL

- Vacuum suction

- Multiple sheet feeding detection

- Long paper feeding

- 800 sheets + 2,100 sheets x 3 trays + 250 sheets

- Maximum size 330 x 1,200 mm (top tray)

*1: A multi-sheet inserter or multi-sheet banner printing inserter is required.

*2: The multi-sheet banner printing inserter is equipped as standard.

Output options:

1. Interface Decurler Module D1

- Real-time paper curl correction

2. Inserter D1

- Cover / sheet insertion

3. Static eliminator D1

- Eliminate static electricity

4. Smart Monitoring Gate D1

- Print inspection

5. High Capacity Stacker A1

- 5000-sheet offset-stacking

- Single and dual combinations

- Stacker cart

- Long sheets Output

High Capacity Stacker A1 with Transport Module

- Connection with 3rd party finisher

- 5000-sheet offset-stacking

- Stacker cart

- Long sheets Output

6. Crease/Two-sided Trimmer D2

- Two-sided trim

- Crease

7. Folder Unit CD2

- Z fold half sheet

- Tri-fold

8. Finisher D6

- Sort / Stack

- Stapling

- Hole punch*3

- Long sheets Output

Finisher D6 with Booklet Maker

- Sort / Stack

- Stapling

- Hole punch*3

- Single fold

- Saddle staple

- Long sheets Output

9. Square Back Fold Trimmer D1

- Face trim

- Square back

|

Offset Catch Tray

|

|

|

Long Catch Tray

|

|

*1: Multi Sheet Inserter or Multi Sheet Inserter for Banner Print is required.

*2: Multi Sheet Inserter for Banner Print is equipped as standard.

*3: Optional

Sales |

Service |

|||

|---|---|---|---|---|

|

Sergio Rebronja |

Matej Meterc | Phone: +386 (0)80 35 65 | ||

| Key Account Manager | COO | Support Portal: podpora.uni-biro.si | ||

| e-mail: servis@uni-biro.si | ||||

| Phone: +386 (0)40 196 049 | Phone: +386 (0)1 530 27 06 | |||

| e-mail: sergio@uni-biro.si | e-mail: matej.meterc@uni-biro.si |