PFI Blade B2+

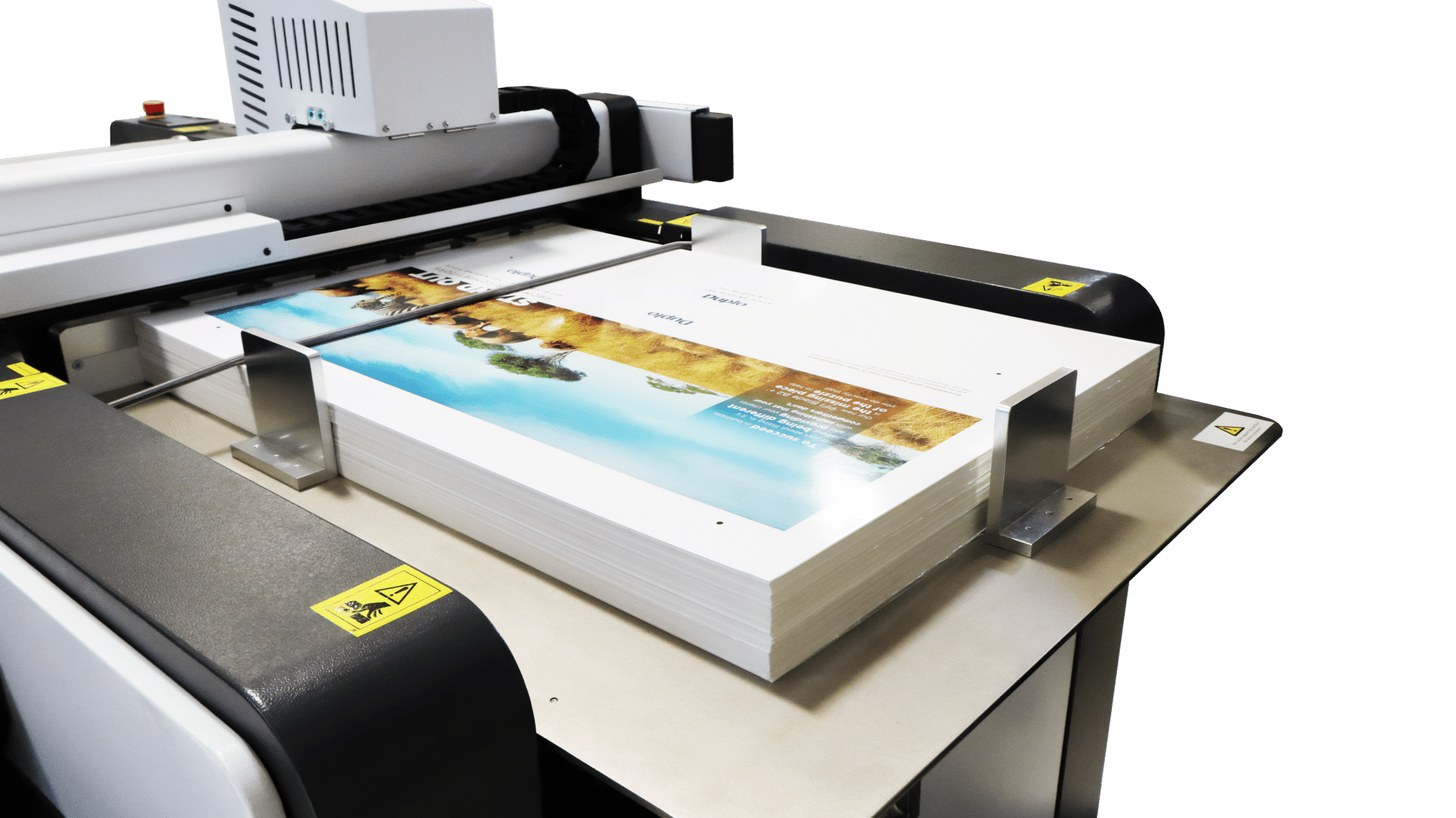

PFI BLADE B2+ Digital cutting table

To succeed in business isn’t about fitting in, its about being different and providing your clients with something that your competitors don’t. Our PFi Blade B2+ is the missing piece of the puzzle to help you do exactly that! Streamline and expand into a new marketplace with the automation and precision for intricate short-run, high-value work, that you can produce for new and existing clients. By diversifying your business offering and giving greater flexibility, you can grow your client base and approach different market sectors with products such as shaped greetings cards, kiss-cut, hanging tags, paper bags and luxury packaging.

Enter new markets with on demand packaging. Featuring smart technology and automated feeding, the PFi Blade B2+ Digital Die Cutter produces custom boxes, pocket folders, and POP retail displays in shorter runs. It comes standard with a number of tools designed to process various types of substrates and thicknesses. Cut, kiss cut, crease and perforate a range of substrates including paper, laminates, boards, adhesives and synthetic stocks dynamically, all on demand.

The press cut tool performs precise cutting on media up to 3 mm thick. Cut intricate shapes with the active knife or drag knife. Score fold lines on packaging using the scoring wheel. Use the optional oscillating knife to pulsate through corrugated, chip boards, and foam boards up to 6 mm thick.

Key Features

- Easy job file preparation and set-up

- Automated registration and changeovers

- Deep pile feeder with 8″ stack capacity

- Quadruple tooling head and DPC Connect software

|

|

|

||

No dies needed

Through the PFi Blade Connect software, the tri-fold tool head follows the lines designed on the cut file to finish applications in any shape. Media is held in place on the flatbed by a vacuum zone, below the conveyor belt as the tool head moves through the blade. |

Simple job setup

Create the cut file in vector programs such as Adobe Illustrator and CorelDRAW to define the desired cuts, kiss cuts, and scores. Export the cut file in a number of supported formats, then upload to the PFi Connect software (PC sold separately) when the job is ready to run. Prepare the printed artwork files by adding registration marks on each corner of the sheet and a QR code. During use, the CCD registration system reads the QR code and automatically opens the corresponding cutting file in the PFi Connect software. It also reads registration marks and compensates for any image shifts to ensure each sheet is finished accurately. |

Automatic feeding system

With a stack height of 100mm, the PFi Blade remains highly productive. Each sheet is vacuum fed with the air knife assisting with sheet separation and then transported to the cutting table. The feed table raises as sheets are fed and can be reloaded without interrupting operation. |

Specifications

| Sheet Size: | Max: 800 mm x 600 mm Min: 210 mm x 297 mm |

|||

|---|---|---|---|---|

| Tools: | Tangental knife, kiss cut knife, Oscillating knife, creasing wheel | |||

| Blade: | Tungsten steel | |||

| Cutting Speed: | Up to 1200 mm / second | |||

| Cutting Thickness: | Up to 6 mm | |||

|

Up to 100 mm | |||

| Options: | Roll to sheet module | |||

| Ideal For: | Packaging Prototypes Shapes business cards Shapes invitations or flyers |

|||

Sales |

Service |

|||

|---|---|---|---|---|

|

Sergio Rebronja |

Matej Meterc | Phone: +386 (0)80 35 65 | ||

| Key Account Manager | COO | Support Portal: podpora.uni-biro.si | ||

| e-mail: servis@uni-biro.si | ||||

| Phone: +386 (0)40 196 049 | Phone: +386 (0)1 530 27 06 | |||

| e-mail: sergio@uni-biro.si | e-mail: matej.meterc@uni-biro.si |